The DTG printer designed with mass production in mind.

What makes the GTXpro B the right choice for your garment decorating business? For starters, Brother builds only industrial-grade garment printers, with print heads, software and firmware that we manufacture. Plus, we’ve developed a proprietary bulk feed system for our own specially formulated inks for even less maintenance time. That attention to every detail means we know that every component is up to the rigors that your business demands. That’s what makes the GTXpro B the cornerstone of your production process and the ideal way to grow your business.

Key Features

- Advanced ink system with new industrial print head

- Production ready design with lower running costs

- Automatic agitation inside ink tank unit

- Additional height sensor

- High quality 1200 x 1200 dpi print resolution

- Environmentally friendly with water based pigment ink

Create high-quality printed garments with minimal training or experience

Unlike traditional labour-intensive processes such as screen printing and embroidery, Direct to Garment printing (DTG) utilizes inkjet printing technology to send a full colour, detailed design directly from a computer to a digital printer with a garment loaded into it.

Piezo print heads then jet opaque white ink and translucent CMYK ink onto the garment and recreate the digital artwork. These inks are water-based, eco-friendly inks that are specifically designed to adhere to fabric when heat cured.

DTG makes it simple to create high-quality printed garments and relieves you from needing highly skilled, extensively trained employees with years of printing experience.

Built to keep up with your high-volume business, no matter how fast you grow.

The Brother GTXpro B gives you more than just substrate flexibility. It also gives you the flexibility to scale up in short order to meet the demands of your growing business, but not before you have the volume to justify it. And you get the flexibility to rearrange your space to better utilise your workforce and create a more efficient production environment.

GTXpro B Ink Chemistry

Take advantage of Brother’s own advanced Innobella Textile Inks formulation to print with greater vibrancy and a larger color range. That chemistry, combined with the next generation AIS (Advanced Ink System) bulk feed feature, gives you the advantage of having even less waste and greater efficiencies on every run. Your prints will maintain their integrity even longer and stand up to multiple washings, all while spending less time on maintenance and refills.

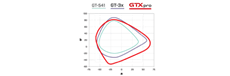

More colours, brighter colours

Take your prints and designs farther and make them more colourful than you ever dreamed possible. Our newly formulated inks actually provide a bolder, wider range of colours that make it simple to reproduce designs more accurately and with a visible increase in vibrancy.

Environmentally friendly

Our bolder, brighter Innobella Textile Inks are water-based pigment inks and are ECO PASSPORT by OKEO-TEX® certified and CPSIA compliant. The bulk packaging uses less plastic thanks to the new reusable tanks so there is less waste and less impact on the environment.

Exceptional washability

Designs printed with Innobella Textile Inks are meant to be worn, not worn out. The special formulation combats the chemicals found in typical laundry detergent and withstands the rubbing and scraping of zippers and buttons. The result is a great looking garment that looks brighter, longer, with proven washability as evidenced by AATCC wash tests, where our inks score 4.0 or higher on every test.

Features and Specifications

| Direct inkjet garment printer |

| 1780mm x 1300mm x 1210mm (with recommended stand) |

| 356mm x 406mm / 14” x 16” |

| 406mm x 533mm / 16” x 21” |

| Approx. 165kg including Platen. Not including stand. |

| Oversize Platen 406mm x 457mm, Adult Platen 356mm x 406mm, Sleeve Platen 108mm x 381mm |

| Water-based pigment ink |

| On demand piezo head |

| 2 print heads: 1 for white inks, 1 for CMYK inks. |

| 1200 dpi x 1200 dpi |

| Single or double for CMYK. Underbase and highlight for white. |

| 18°C – 30°C Degrees / 35% – 85% Humidity % |

| 10°C – 35°C Degrees / 20%-85% Humidity % |

| USB, File output, LAN. |

| AC 100V-240V, 50/60Hz ± 1Hz |

| 0.8A (average) (Reference: 0.4A – during circulation) |

| Heat press machine can be used at 180°C (356°F) and 35 seconds duration. For higher volume production, a conveyor oven is recommended to be used at 160°C (320°F) for three and a half minutes. Time and temperature may vary depending on which manufacturer’s dryer is used. |

| Before printing, apply pre-treatment using either a manual or automatic device and then dry garment using a heat-press, being sure to follow all manufacturer’s instructions. Pre-treatment is necessary for white ink. |

| Windows 8.1 (64bit), Windows 10 (64bit), macOS 10.14 Mojave, macOS 10.15 Catalina. |

| USB2.0, LAN(10BASE-T, 100BASE-TX, 1000BASE-T), USB Flash Memory(Under 32GB, FAT32 format). |

| 2GHz CPU (minimum recommendation) 4GB RAM (minimum recommendation) |

| XGA (1024×768) (minimum recommendation) |

| Adobe® Photoshop CS6/CC, Adobe ® Illustrator CS6/CC, CorelDRAW ® 2018/2019 (Windows) |